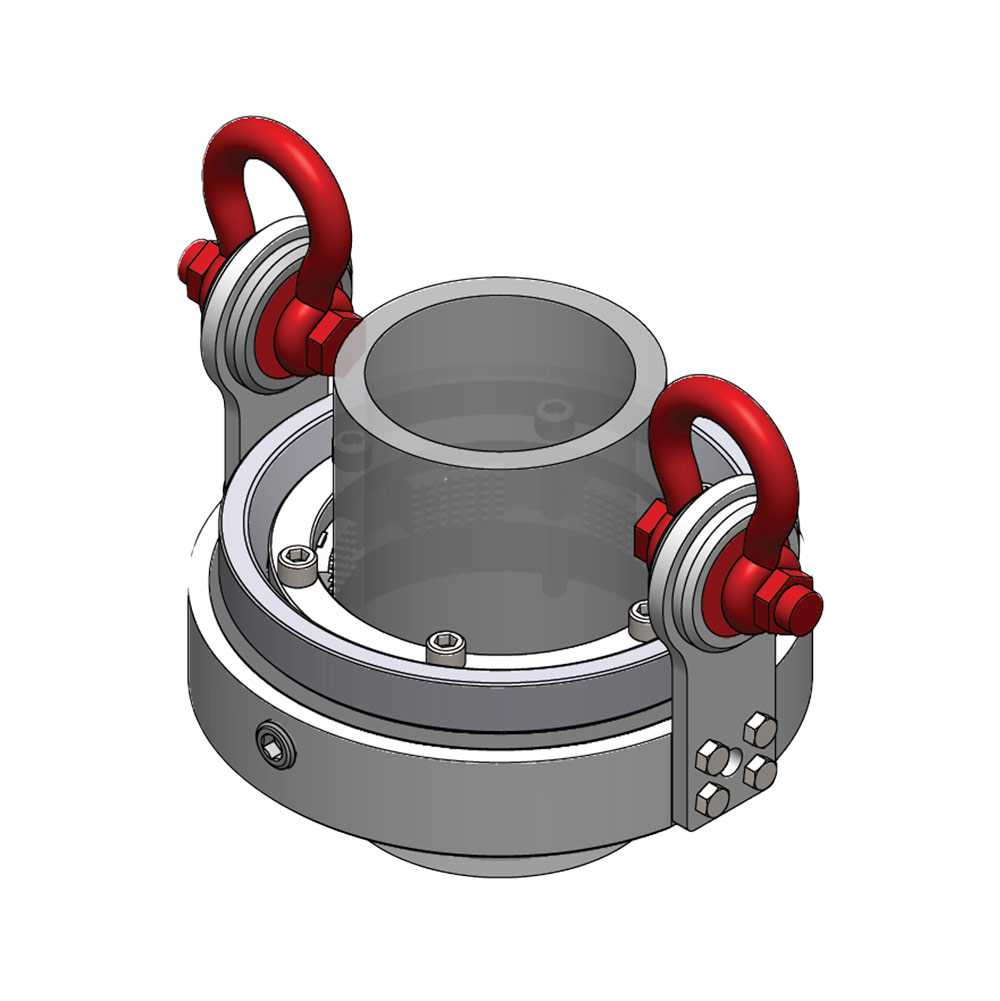

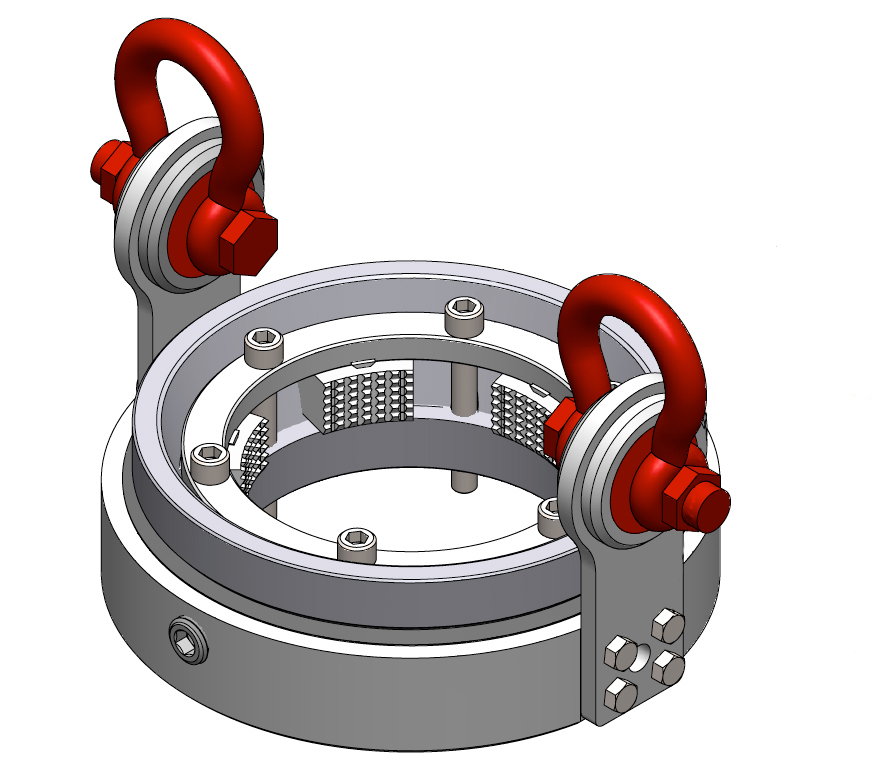

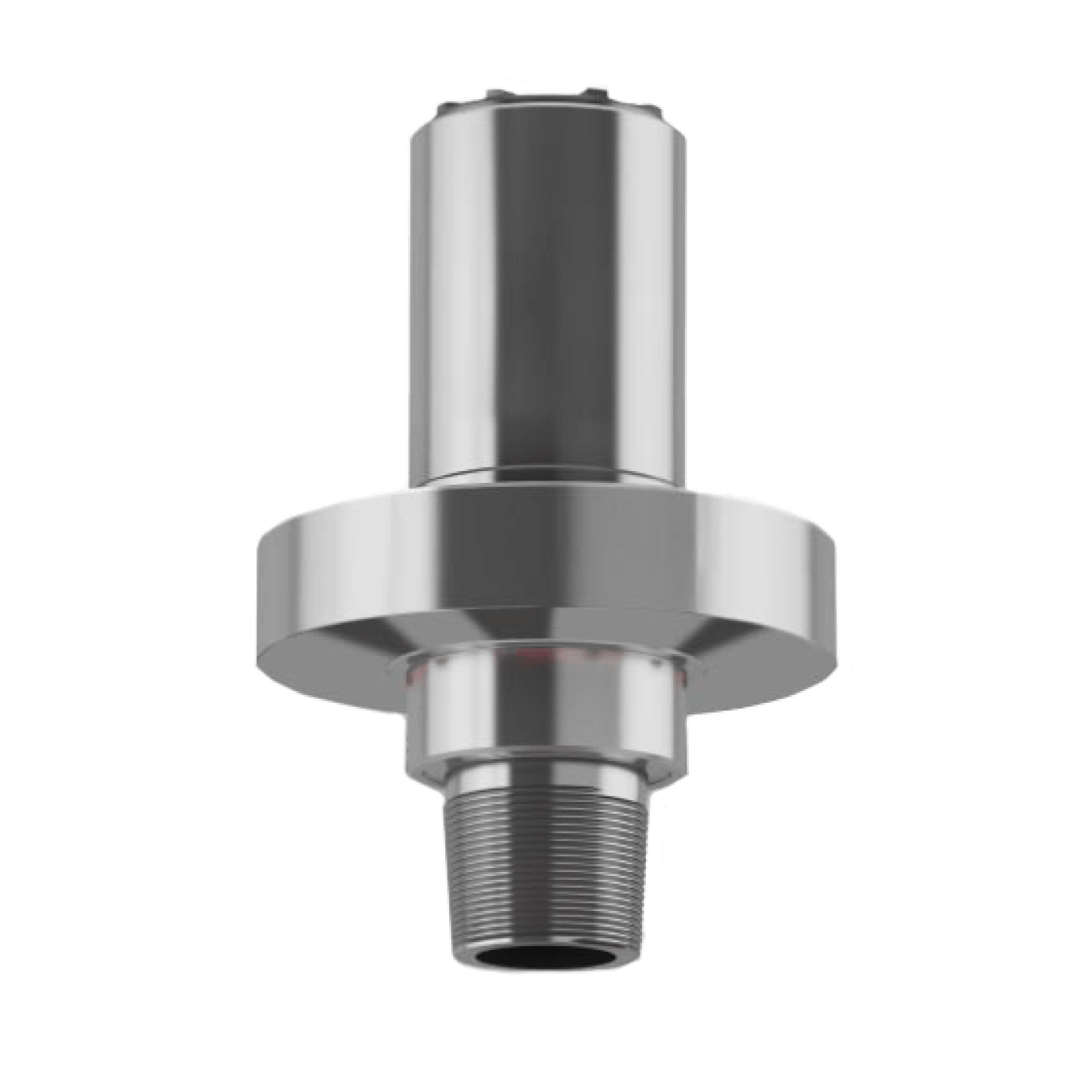

CRT NUBBIN

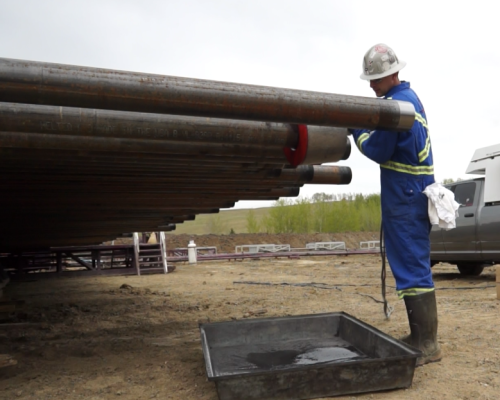

The ProTorque CRT Nubbin was designed to protect both the CRT packer cup and the tubular connection when a Casing Running Tool is used. Damage can occur to the seal and thread profile of the connection if there is misalignment when inserting the CRT. Without a CRT Nubbin, damage can occur to the packer cup as it passes through the connection. The nubbin’s improved stab flank reduces interference when inserting the CRT.

#RedefineTRS™

FEATURES

Specialty sizes and connections available upon request

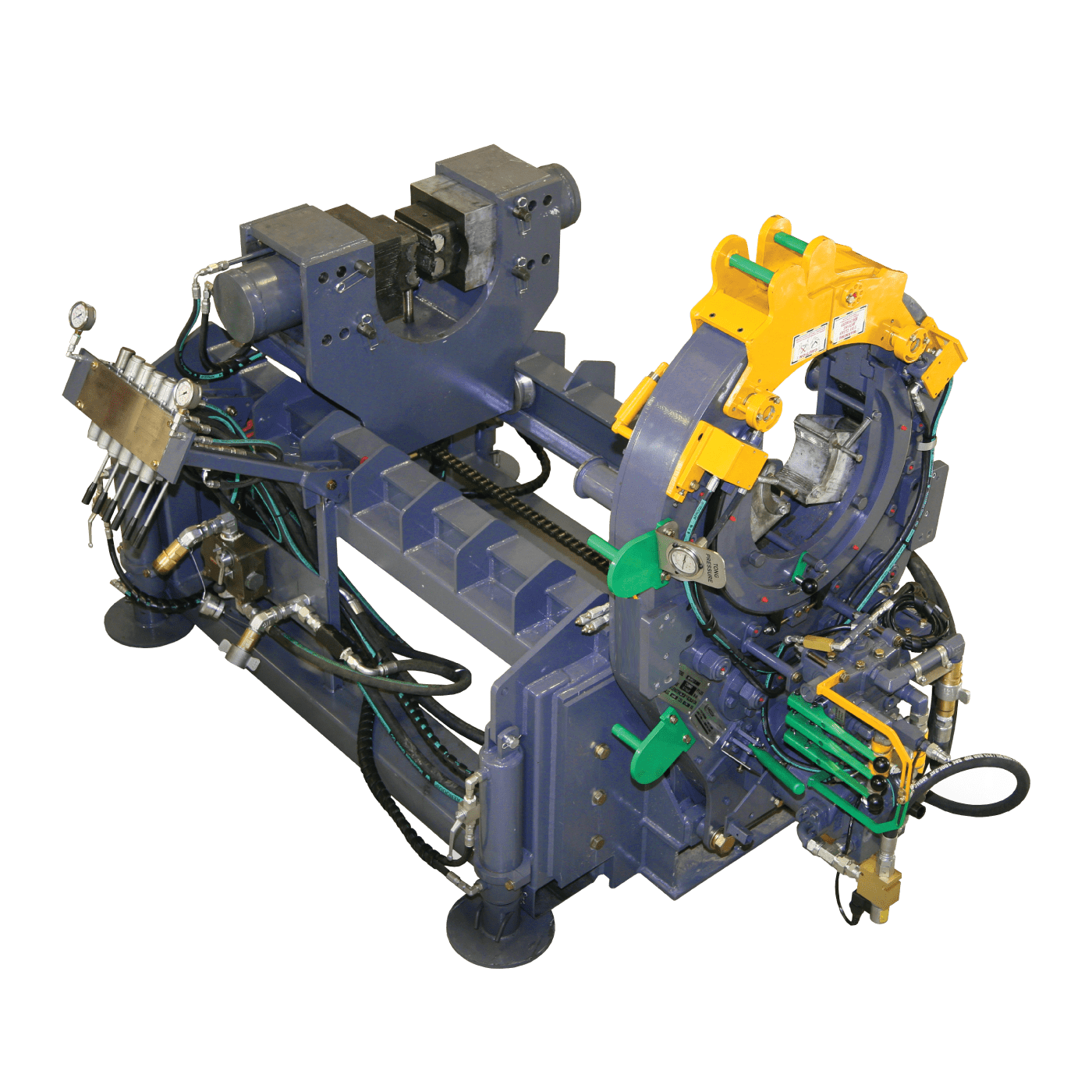

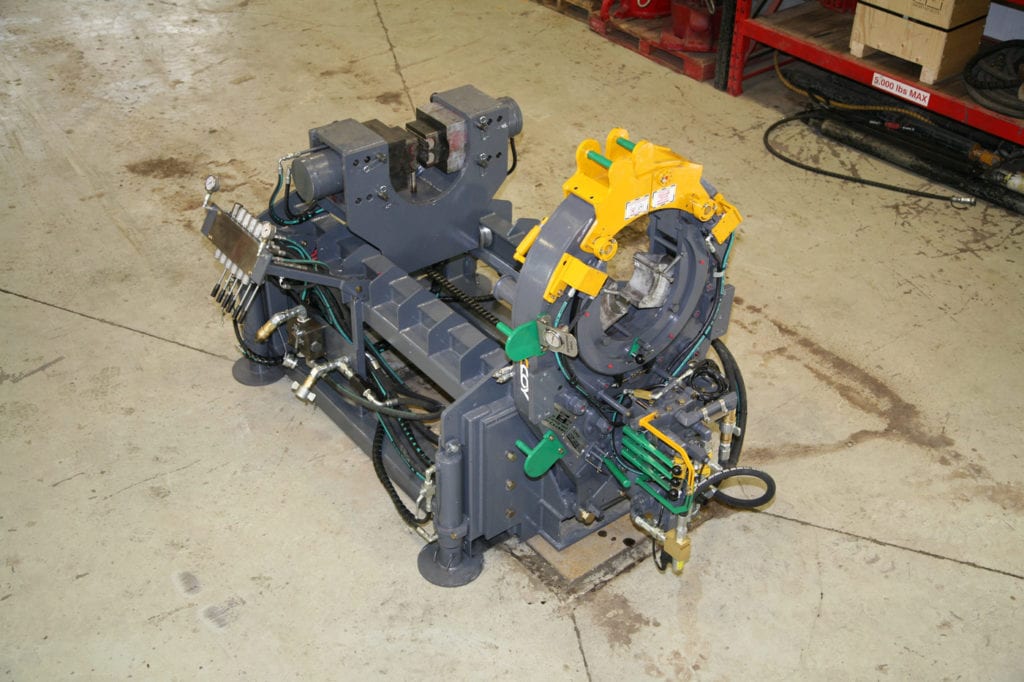

Inline time savings equates to more productive rig time & seamless operation

7 degree stab flank to protect packer cup and allow easy transition into the tubular

Full circle pry bar hole for easy removal

Reduced thread engagement for more efficient operation

Increased packer cup life

SPECIFICATIONS

Heading #3 | Heading #3 |

|---|---|

SIZING | 4.5 – 13.38” (114.3 – 339.7 mm) |

AVAILABLE CONNECTIONS | API and most premium manufacturers |

ALL SERVICES, ALL LOCATIONS

CONTACT US TODAY