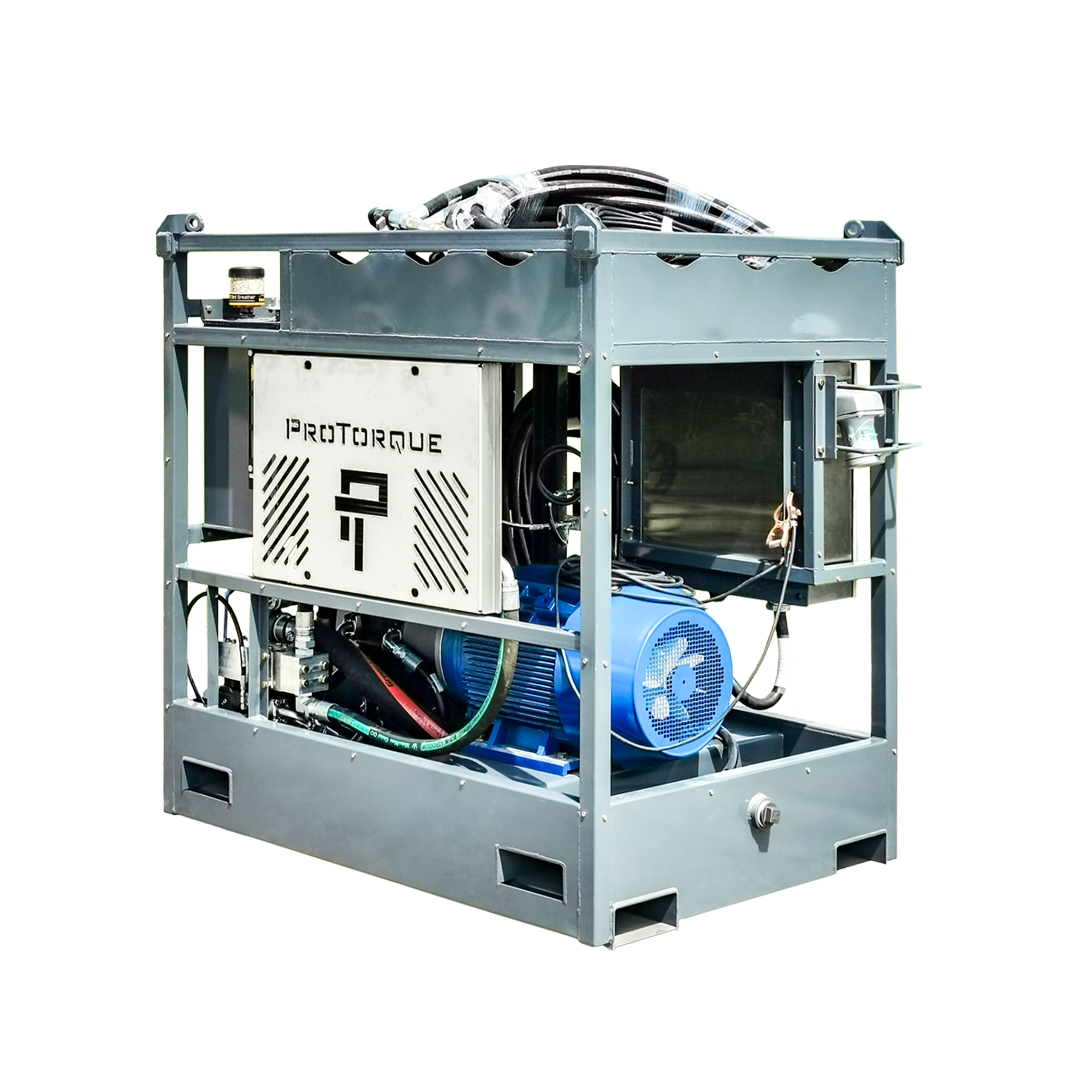

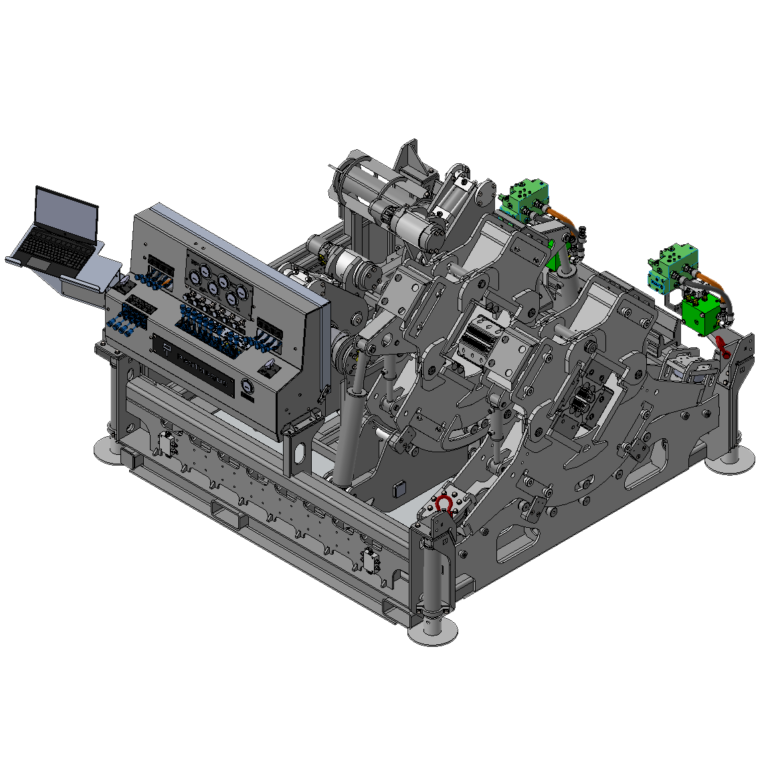

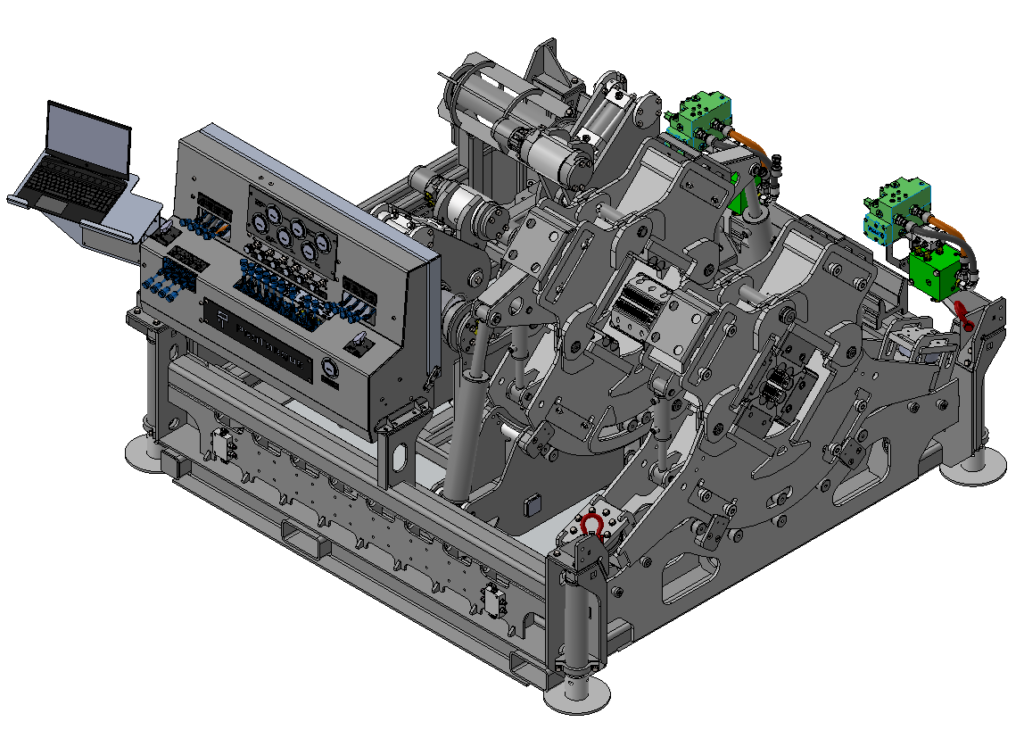

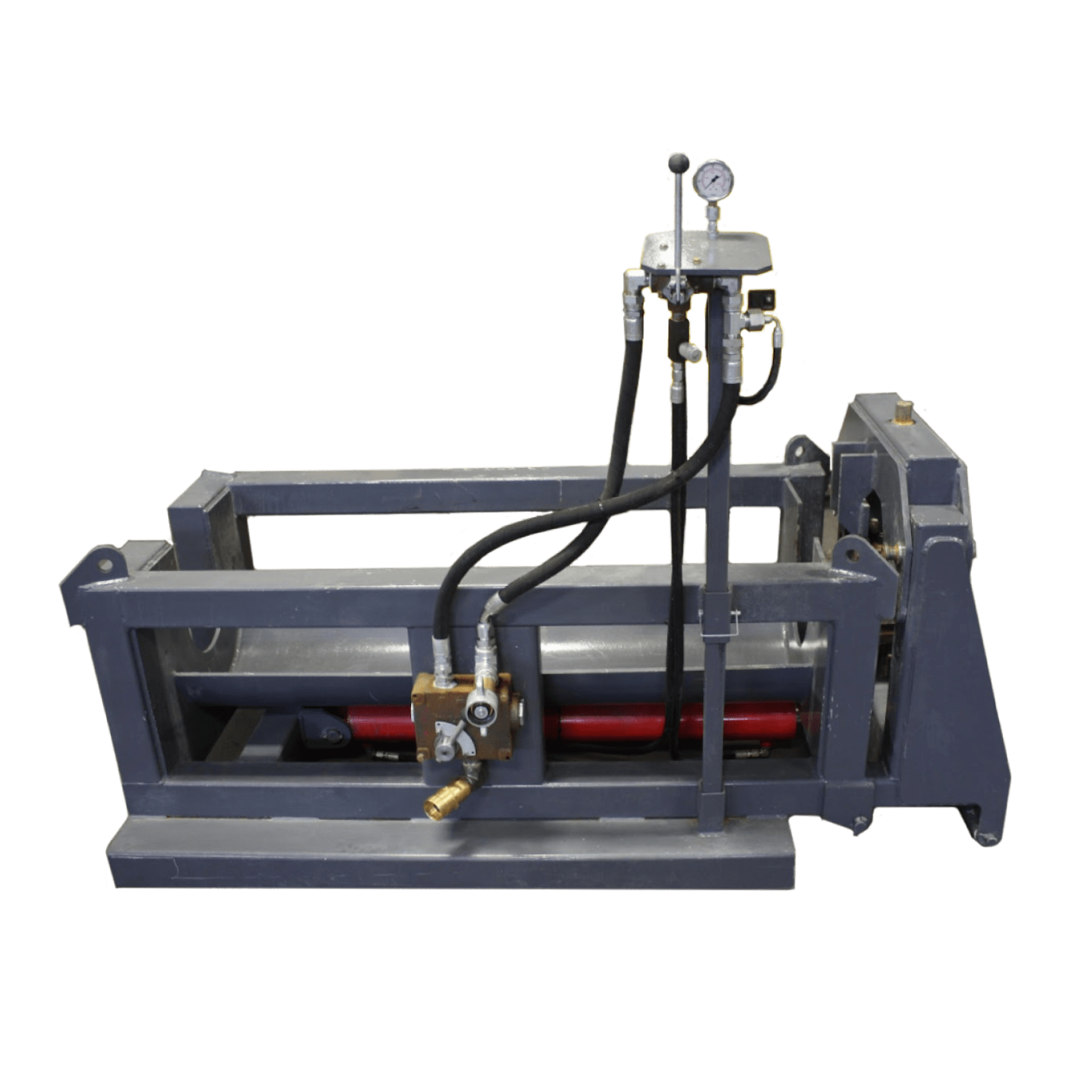

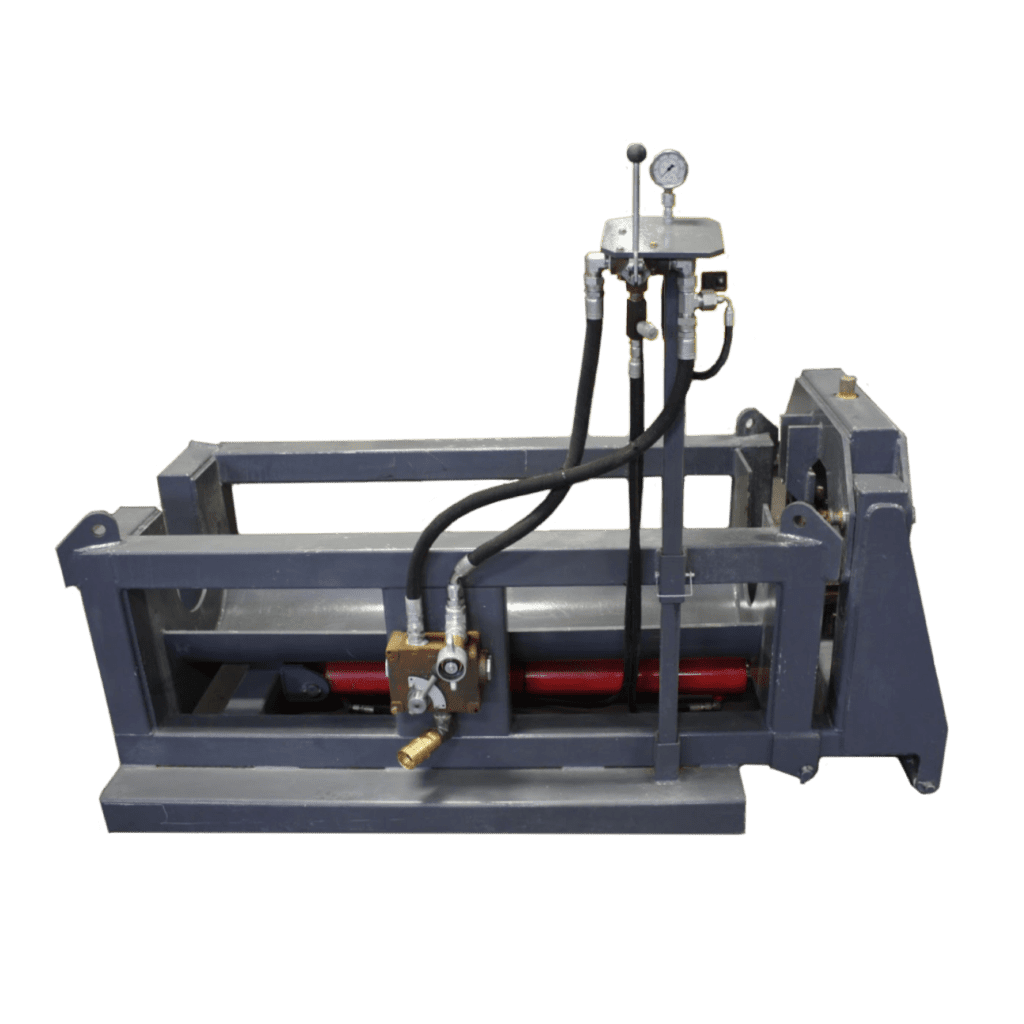

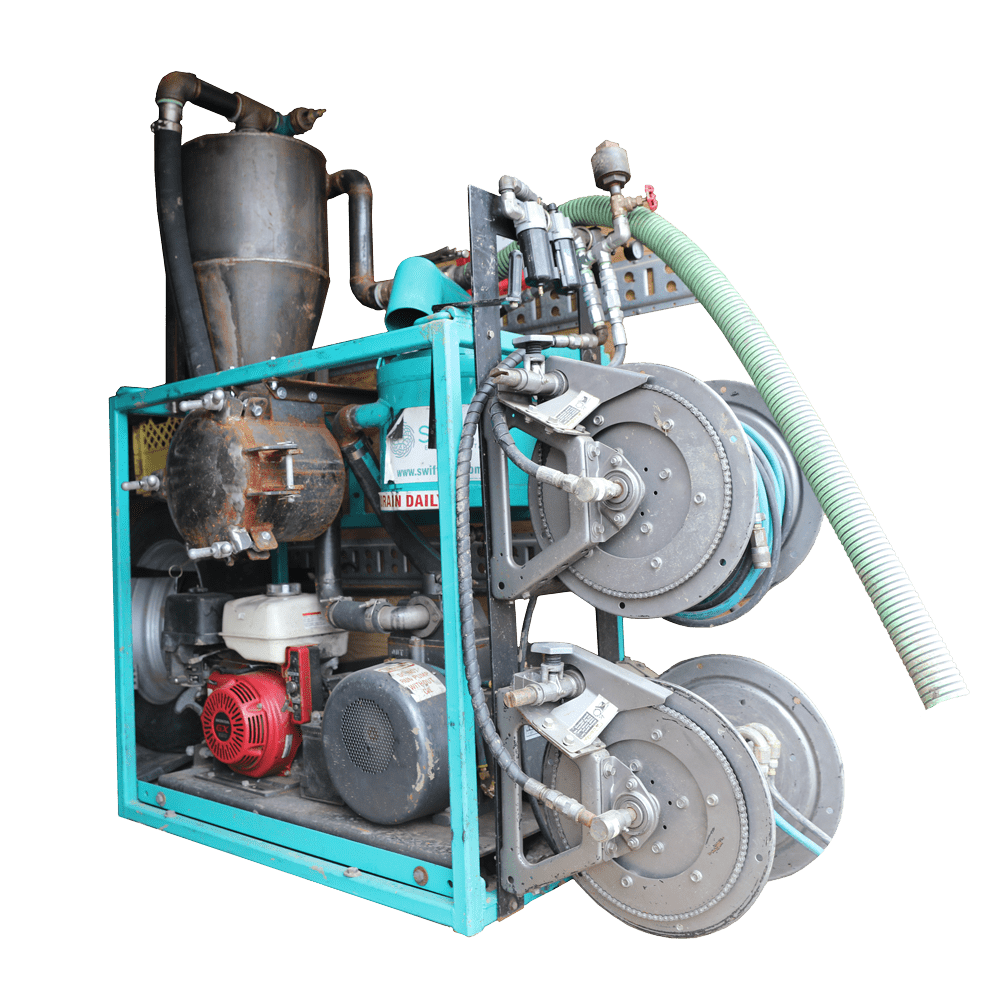

Electric Hydraulic Power Unit (eHPU)

ProTorque’s Electric Hydraulic Power Unit (eHPU) transforms rig operations with a focus on efficiency, reliability, and reduced downtime. This rig-integrated unit draws power directly from the rig grid, replacing diesel-powered HPUs. Experience streamlined operations, simplified maintenance, a significant impact on rig time savings and a reduced environmental footprint.

#RedefineTRS™

FEATURES

Seamless integration with existing rig power, eliminating separate fuel-based units

Provides fewer tong trucks in use and on the road

Faster setup and tear-down compared to traditional hydraulic power sources

Engine-free design minimizes failure points and increases uptime

Fewer moving parts reduce maintenance requirements and downtime risks

Eliminates fuel expenses and lowers ongoing maintenance costs

ALL SERVICES, ALL LOCATIONS

Contact Us today!