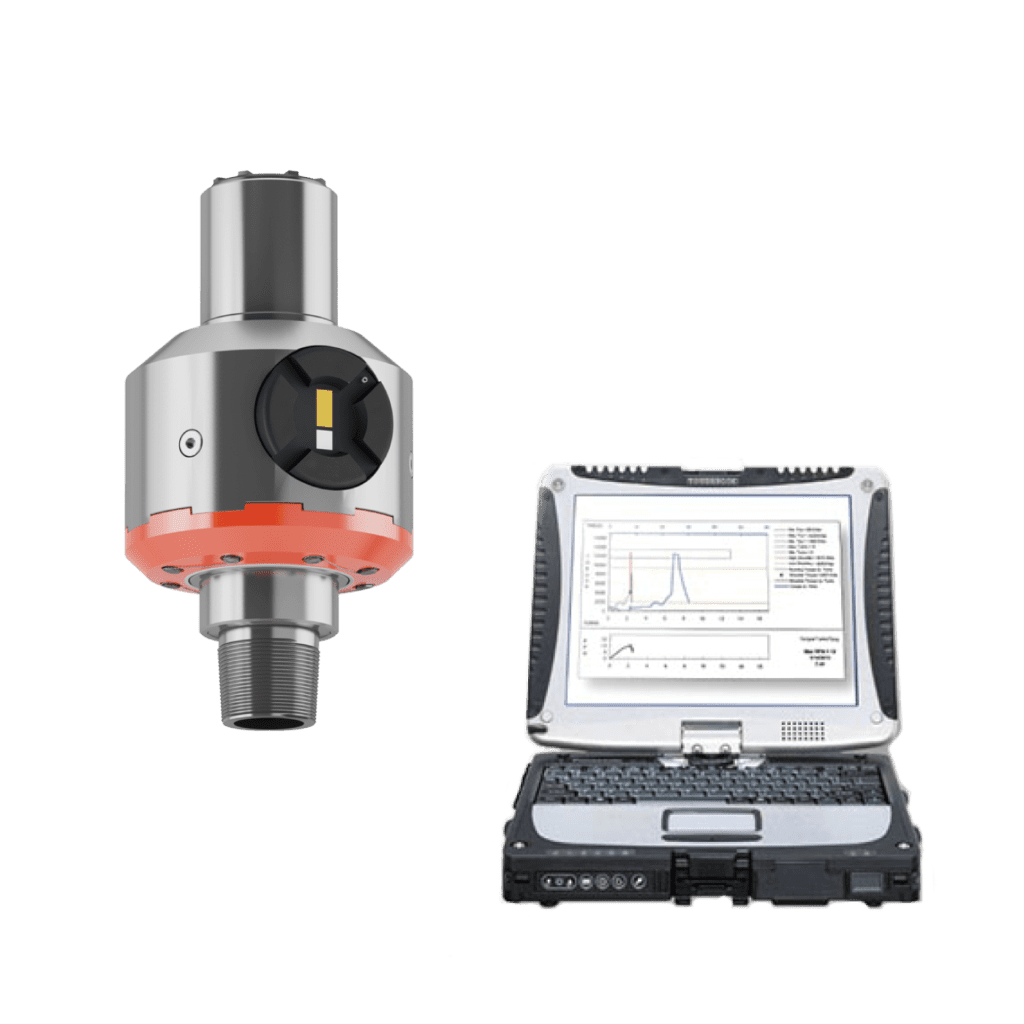

HOOK LOAD & TORQUE VERIFICATION

The Torque Sub is used to regularly verify the top drive and rig tong torque outputs. This is to ensure that they are accurate and to reduce damage to the rotary shoulder connections during make-up. Regular verifications help to prevent downtime, equipment failure, repair costs and can extend the service life of your drill pipe.

#RedefineTRS™

CONSEQUENCES OF INCORRECT MAKE-UP TORQUE

1 in 20 wells experience a “back-off” or “twist-off” event

The average cost is $400,000 per event

30-35% of Top Drives deliver inaccurate drill pipe connection torques

1 in 4 Top Drives are out of calibration by more than 10%

A variety of factors can cause a Top Drive to apply errant torque or hookload. This might include mistaken system settings, temperature variations, plumbing leaks, and SCR or voltage issues. These factors can go undetected and cause incorrect torque values. There is only one way to ensure a Top Drive is delivering correct make-up torque to your connections – by directly measuring the torque being applied using a direct measurement tool.

SPECIFICATIONS

Heading #3 | Heading #3 | |

|---|---|---|

TORQUE CAPACITY | 40,000 – 50,000 ft/lbs (54,200 – 67,700 Nm) | |

HOIST CAPACITY | 750,000 – 1,000,000 lbs (375 – 500 tons) | |

WEIGHT | Approx 350 lbs (160 kg) | |

SUB LENGTH | 18.6 – 22” (472.4 – 558.8 mm) | |

**Specialty weights, lengths and capacities will depend on customer drill pipe specifications** |

Solution

Since a direct (not derived or estimated) Torque / Hookload and RPM measurements are captured by the Torque Sub, it removes additional calculations, correlations or guesswork. Measurements captured allow an operator to adjust the set points on the Top Drive or EDR to maximize the accuracy and drilling parameters.

** Calibration may require manufacturer-specific servicing of equipment**

ALL SERVICES, ALL LOCATIONS

CONTACT US TODAY